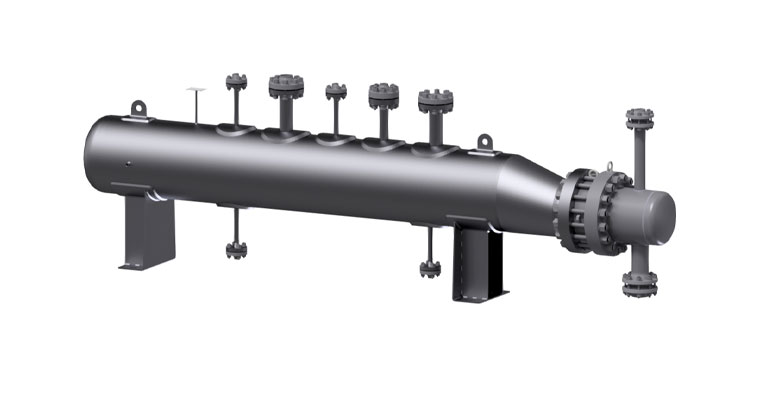

Tube bundle heat exchanger

Liquid cooler/heater - Oil cooler - Steam condenser - Steam generator - Exhaust gas heat exchanger

The tube bundle heat exchangers are primarily suitable for heat transfer between different liquids and gases with or without phase change. Excellent results are achieved when heating or cooling liquids and gases using water, thermal oil, saturated steam, etc. The standard series includes 6 sizes with heat transfer areas from 0.5 to 500 m2

Area of application

Shell and tube heat exchangers have great versatility in their use and are used in various industries, e.g. E.g.:

- Power plant technology

- Machinery industry

- Gearbox construction

- Chemical industry

- Process engineering

Structure and mode of operation

The heat exchangers essentially consist of a housing and a tube bundle insert. The housing is a welded construction and includes all connection, connecting and fastening elements. The smooth tube bundle to be installed for this purpose is provided as a two-way version as standard. The chosen concept with U-tubes (U-design) or floating tube sheet (D-design) or with a fixed compensator (K-design) enables large changes in length between the jacket and bundle as a result of thermal expansion.

Materials

The following material combinations are possible (special materials on request):

- Jacket: Steel St37-2, St37-2 hot-dip galvanized, stainless steel V2A/V4A

- Lid: Steel St37-2, St37-2 coated with RILSAN, stainless steel V2A/V4A

- Cooling tubes: SF-CU, CuZn20Al, CuNi10Fe, CuNi30Fe, stainless steel V2A/V4A

Types

Type G: Tube bundle heat exchanger

Universal tube bundle heat exchanger for liquids and gases. Various materials are used, including the highest quality stainless steels with high corrosion resistance. Operating pressures of up to 800 bar are possible. The standard series includes 6 sizes with transmission areas up to 150m2.

Type GK: Shell and tube condenser

This type is used to heat liquids or gases by condensing saturated steam, superheated steam or refrigerant. Depending on the application, the steam is on the pipe or shell side. Several variants in vertical or horizontal position with up to 20MW transmission power are available.

Type GV: Tube bundle evaporator

The GV type is used to cool liquids by evaporating refrigerants, especially ammonia. The series includes horizontal or vertical versions with removable or permanently welded tube bundle inserts.

Type GD: Steam generator

The GD series is used for the indirect generation of low or high pressure steam. The heating medium used is primarily steam, hot water or thermal oil. The most horizontal versions are manufactured with the appropriate test certificates depending on the print and content.

Type GA: Exhaust gas heat exchanger

The GA series is used to utilize waste heat from flue gases. The heat used by thermal combustion processes, CHP systems, etc. is given off to hot water, thermal oil or, for example, to the combustion air. In special applications, the condensation heat of flue gases can also be used.

Type GS: Safety heat exchanger

Using a double pipe eliminates the risk of both media mixing. The gap is filled with a barrier liquid, which absorbs the thermal expansion and controls the tightness of the pipes via a pressure switch. Any breakthroughs are reported automatically.