Fin tube heat exchanger

Fin tube heat exchangers as air-cooled liquid coolers - air heaters - heat recovery registers - forced air coolers - compressed gas coolers - oil coolers - generator coolers - evaporators - condensers

Fin tube heat exchangers from ETS AG are primarily used in the heating and cooling of liquids using gases or vice versa. Heat transfer can be carried out using various media such as water, brine, saturated steam, hydraulic or lubricating oil, thermal oil, as well as condensing or evaporating refrigerants. Thanks to their finned design, finned heat exchangers can accommodate a large active external surface in a small volume. Our series include various heat transfer surfaces from 0.1 to 8,000 m².

Areas of application

Fin tube heat exchangers are used in a variety of ways and are used in a wide variety of industries, for example:

- Power plant technology

- Machinery industry

- Paper industry

- Chemical industry

- Process engineering

- Environmental technology

- Heating and ventilation technology

Structure and mode of operation

The finned heat exchangers essentially consist of core tubes with mounted or pressed-on fins, a housing and several collectors or deflection boxes. Depending on the required operating data, the material flow is individually adjusted. Thanks to special design variants, even large thermal expansions of the pipes can be easily absorbed. Special tube/lamella material combinations are available for applications with high corrosion requirements and high operating pressures (up to 800 bar).

Materials

The following material combinations are possible:

- Pipes:

- copper, copper-nickel, steel

- stainless steel

- Heat exchanger fins:

- aluminum, copper,

- stainless steel

- Housing

- Aluminum, steel, galvanized steel,

- stainless steel

Types

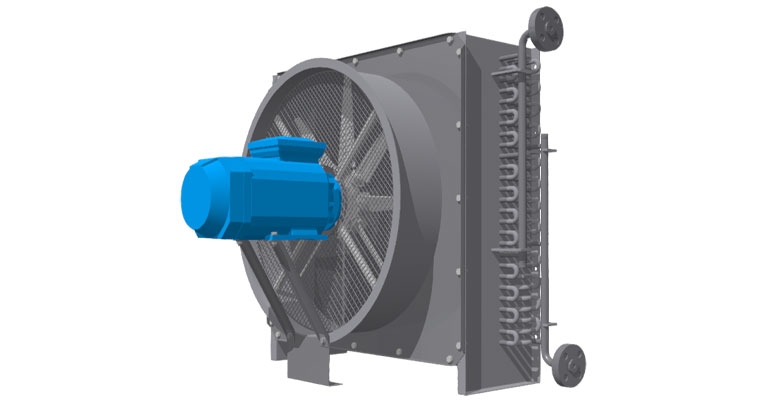

Type FLNB

The air-cooled oil coolers of the FLNB series have been designed according to the latest findings in thermal technology and consist of aluminum elements with a housing/hood and fan. The standard series includes 12 types with a maximum cooling capacity of 150 kW. The main application is the recooling of hydraulic, lubricating or transmission oil.

Type LK

Type LK recoolers are usually required to dissipate excess heat into the ambient air. In addition to applications in liquid circuits such as water, brine, etc., this type can also be used as a capacitor. The standard series includes 24 types with heat transfer surfaces of max. 1200 m2.

Type LBD

This type is used to heat process air or process gas by condensing saturated steam or superheated steam. Depending on the requirements, various materials such as galvanized steel, stainless steel, etc. are available. Applications with high operating pressures up to 800 bar with corresponding test certificates are also possible.

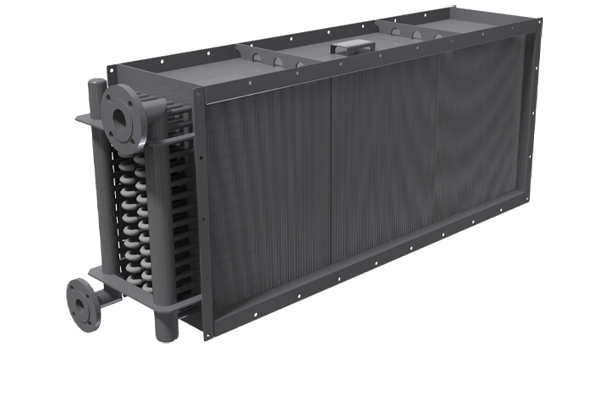

Type LBF

Universal finned heat exchanger is used for heating and cooling gases and liquids. Various material combinations from copper, copper-nickel, brass, aluminum to completely stainless versions for high corrosion resistance are possible. The individual elements can have a length of max. 8000mm.

Type LBW

Heat recovery from already used exhaust air is becoming increasingly important. The LBW series is specifically designed for the valuable use of waste heat. Even large exhaust air flows at low temperatures can still be used.

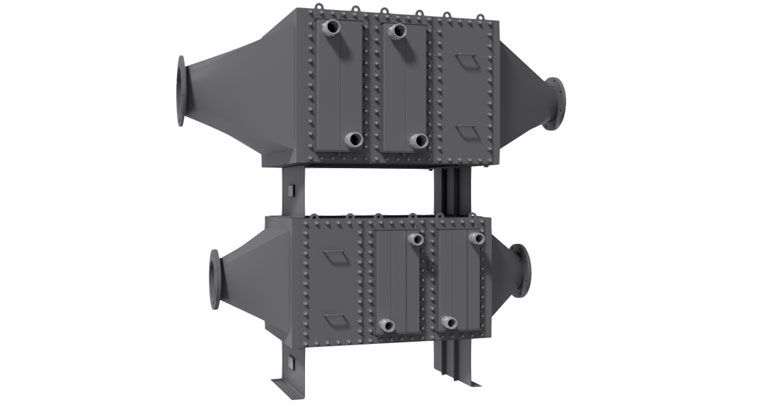

Type KKG

High-pressure coolers represent a special application. When compressing natural gas or technical gases, final pressures of up to 800 bar are achieved. With the KKG series, the recooling of compressed gases can be achieved easily and safely.